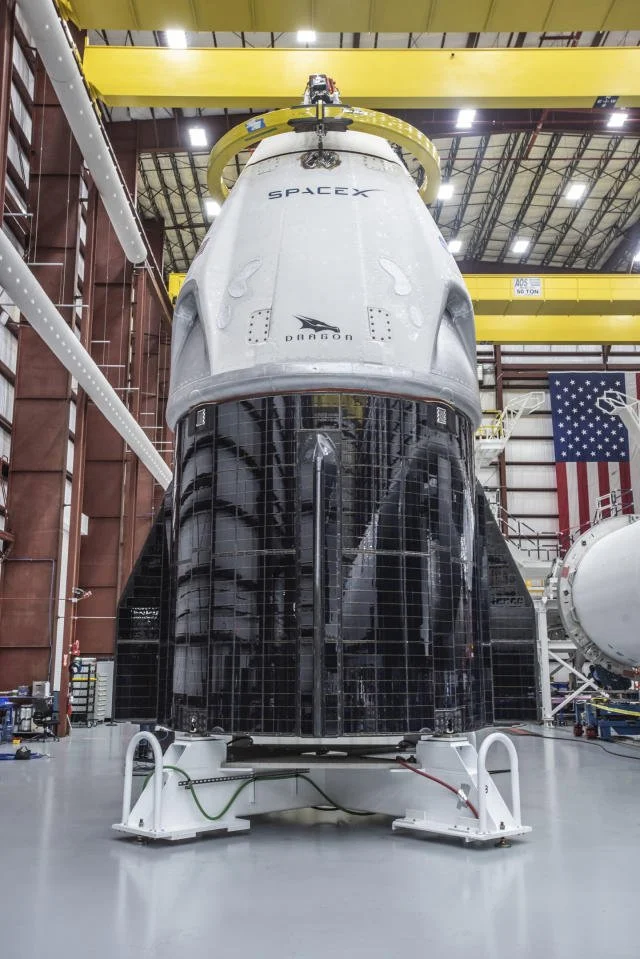

Design Engineer for Dragon Structures enabling faster production and refurbishment of the only U.S. human-rated, reusable orbital spacecraft. Responsible for the redesign of all the solar pyrons, developing the VAST waste system, and running updated analyses on the access panels.

Solar Pyron Redesign

Commonized the Crew and Cargo solar pyrons, oxidized PAN fiber pieces used as strain isolators in between the carbon fiber backshell and solar panels on the trunk, to decrease part count by 16%. Eliminated solar array production issues by widening diode plate cutouts while maintaining a constant bonded surface area and extending the vent channels to accommodate for wire harness routing. Led DFM and communications with the supplier to ensure on-time delivery for a CRS-30 cut-in.

VAST Waste System

Designed and analyzed the VAST Waste System’s Commode Bracket from start to finish using ribbed features to increase stiffness, counterbore holes for increased holding strength, and a modular assembly process for ease of in-space installation. Utilized human-centric design principles to consider aesthetic and functional parameters of the design, such as the finish of the material and the angle of the commode bracket, respetively.

Access Panel Analyses

Ran detailed structural analysis on six access panels on the Dragon spacecraft by correlating the deflection pattern of the most critical load cases in the Femap integrated model with the stiffnesses of the connecting features around the access panel in ANSYS. Identified specific load cases that would cause negative margins and suggested detailed design changes to bring the designs to positive margins.